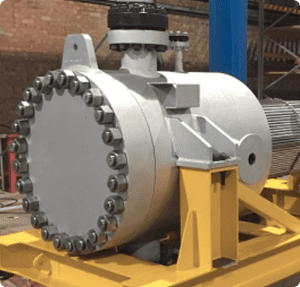

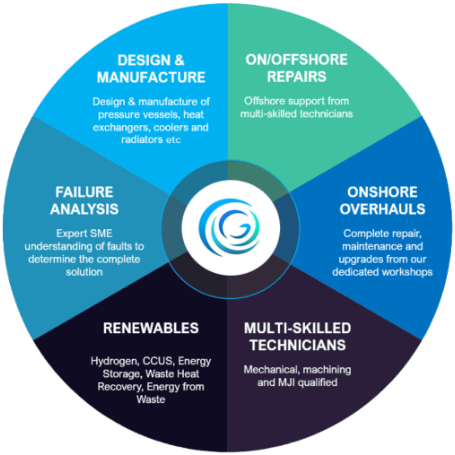

We’re also equipped to design bespoke heat transfer solutions for companies with exacting requirements that can’t be met by conventional or “off the shelf” heat transfer technologies, including units designed to cope with corrosion, extreme pressures and/or cyclic thermal stress.

We’ve designed complex heat transfer systems for blue chip companies across the Caspian region, Europe and the rest of the world – including chemical manufacturers, energy companies and oil majors who frequently need bespoke equipment capable of operating in extremely confined or restricted, sour and inhospitable environments.

We also design and manufacture heat transfer equipment for renewable and alternative energy companies.