Published in NDT & Inspection

Challenge

Client had a vessel carrying high pressure steam. Previous manual UT thickness checks showed dubious results and highlighted a potential concern.

Solutions

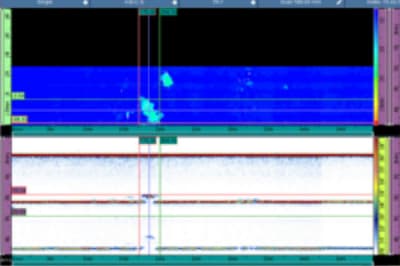

- Glacier Energy provided high resolution Phased Array Hydroform to corrosion map the vessel dished end and identify the corroded area

- We supplied information on the remaining thickness of the internal steam side of the vessel and provided full C-scan “mapping” of the area of concern.

Benefits

- Mobilised offshore in less than 24 hours.

- Client was able to plan and arrange vessel repairs and arranged to cut out at local lower circ seam location and replace the dished end

- This resulted in a potential high-level incident being avoided with non-intrusive inspection from highly skilled technicians