Overview

Services

Glacier Energy is a specialist provider of onsite machining equipment and services, performed by highly experienced and multi-disciplined Grade 1 technicians. We have an established global track record delivering major projects across the energy sector, for both topside and subsea applications and well as onshore sectors including construction yards, petrochemical and power generation.

Based on our market-leading capability, we are a specialist onsite machining services partner to various original equipment manufacturers (OEMs). Furthermore, our highly responsive and in-house design and manufacturing teams can provide custom engineering solutions to solve our clients’ most technical and complex projects challenges.

We are committed to the highest standards of safety and service quality and take pride in our “right first time” reputation and culture. Glacier Energy has bases across the UK, as well as established partners in the Middle East and in the USA in order to meet international demand for our specialist knowledge, services and expertise.

- Pipeline Services

- Flange Facing Machining

- Global Decommissioning Support Services

- Phased Array Ultrasonic Testing (PAUT) Services

- OEM Special Type Flange Machining

- Heat Exchange Machining

- Drilling, Tapping & Reaming Services

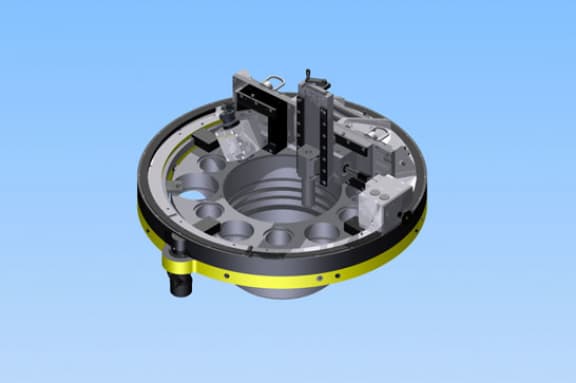

- Line Boring

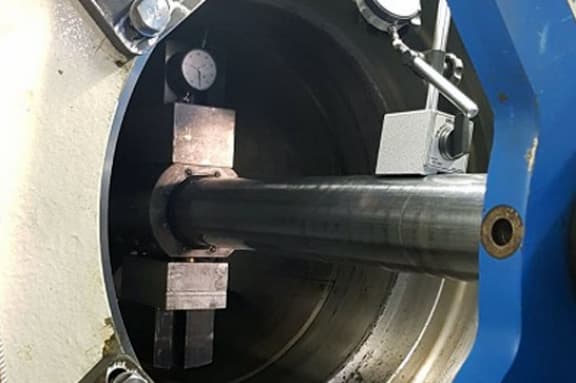

- Shaft & Journal Turning

- Milling

- Wellhead Services

- Mechanical Inspection Services

- Engineering Solutions

Need advice or help with your Machining requirements?

Do you want further details about our wide range of Machining products and services? You can call us on 01333 425517 or fill out the form below and we'll get back to you.